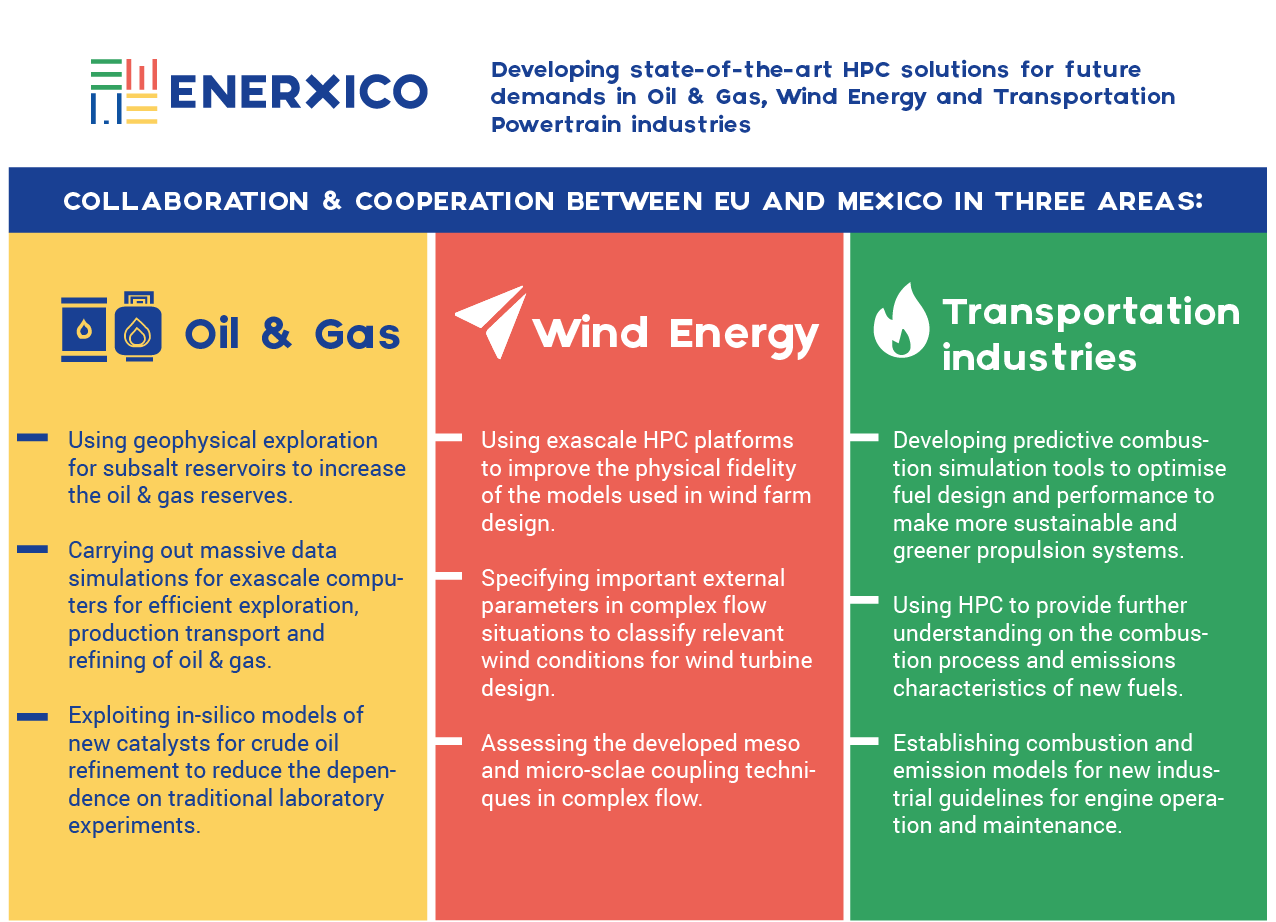

After more than two years of research, the collaborative project between Europe and Mexico ENERXICO comes to an end with major results and contributions in the context of Exascale High-Performance Computing (HPC) and data intensive algorithms for different energy sectors. Specifically, the project, coordinated by the Barcelona Supercomputing Center (BSC) in Europe and the Instituto Nacional de Investigaciones Nucleares (ININ) in Mexico, focused on developing advanced simulation software solutions for oil & gas, wind energy and transportation powertrain industries.

Image 1. The ENERXICO consortium in Ciudad de México

“ENERXICO is the perfect example of how cooperation between two regions, in this case the EU and Mexico, can lead to important advances in the knowledge of HPC exascale techniques”, said José María Cela, ENERXICO´s European coordinator and Director of the Computer Applications in Science and Engineering (CASE) department at the Barcelona Supercomputing Center.

“The exascale-ready application codes developed within the framework of ENERXICO have already benefitted Mexico´s national petroleum company Pemex, proving that the project’s research is very valuable in optimising oil and gas industry in this country”, commented Jaime Klapp, ENERXICO´s Mexican coordinator and head of the Computational Fluid Dynamics group at ININ, as well as the co-founder of the Cinvestav-Abacus supercomputing centre.

HPC in Oil & Gas industries

ENERXICO´s research on oil and gas focused on expanding the impact of HPC in seismic imaging by analysing and comparing state-of-the-art modelling and inversion software, applied to realistic scenarios relevant to Mexican oil and gas prospects. To do so, the researchers provided different use-cases and had to take into account the geological complexities and uncertainties of the subsurface models.

In this context, the project has developed the Black Hole (BH) code, the first SPH based code for the numerical simulation of oil reservoirs, which has been capable of performing simulations with billions of “particles” or fluid elements that represents the system under study. This code contains improved multi-physics modules that automatically combine the effects of interrelated physical and chemical phenomena to accurately simulate in-situ recovery processes.

HPC in Wind Energy industry

ENERXICO’s work on wind energy focused on designing tools to understand and predict atmospheric scales of motion relevant for the operation and performance of wind turbines and farms in complex wind situations.

The design of a wind farm encompasses many complex steps and it is difficult to estimate the adequate size and where to locate the turbines to optimise production. In this context, the researchers have included characteristics of the wind flow that belongs to scales well above the size of a wind farm into CFD (Computational Fluid Dynamic) simulations in order to increase its accuracy since local flow is usually influenced by the dynamics of mesoscale and synoptic scales, although this information is not realistically included in CFD models. The mesoscale dynamics are resolved by means of the model WRF (Weather Research and Forecasting), that uses as input the information contained in global models (e.g. ERA5). Global models resolve the large scale dynamics over coarser grids (around 30 km), that are downscaled to a few kilometres with the help of WRF (typically 3 km to 1 km). In the case of microscale models (Alya in ENERXICO), local phenomena are resolved with fine grids with resolution in the order of metres but in small domains (typically 30 km x 30 km).

Therefore, by using WRF and coupling it to a CFD model the researchers made use of the information in the cascade from large scale dynamics to local microscale characteristics of the wind flow over the wind farm.

HPC in the Transportation industry

Finally, ENERXICO has also developed advanced modelling tools for high-fidelity combustion simulations to study the use of renewable fuels in future sustainable transportation systems. Overall, it brought together state-of-the-art automotive technologies with current and future fuel requirements within the framework of exascale simulations of combustion engines and experiments.

The ENERXICO project allowed the development of computational models for the study renewable fuels of OMEx-type under Engine Combustion Network (ECN) Spray A conditions. In particular, a blend of different OMEx fuels and OME1 have been investigated and compared to dodecane, in order to understand the fundamental differences in combustion performance of these synthetic fuels. The modelling framework consists of a high-fidelity LES approach together with a Eulerian-Lagrangian spray model and flamelet-based turbulent combustion model. Results indicate ignition delay time and lift-off length according to the fuel reactivity properties, with the OMEx fuel performing similarly to dodecane. Flamelet calculations show that ignition of the oxygenated fuels is in general similar to that of dodecane, but it occurs at higher mixture fraction values due to the differences in stoichiometry. The reaction front for OMEx is stabilized at distances closer to the nozzle than for dodecane, and the flame shape and internal structure is different from dodecane.

Among others, the researchers performed highly controlled experiments, which replicate the operating conditions that such advanced fuels will find in the combustion chamber of an engine in an optically accessible vessel. This meant filling up a test volume with air of controlled composition at high pressure (up to 150 bar) and temperature (up to 730ºC), and injecting the fuel through a single-hole injector at realistic injection pressure (1500 bar). Compared to a real engine, where multi-hole injectors are used, and wall interaction as well as piston movement can occur, this was a much more simplified environment. However, conditions of the experiments were highly controlled, and highly advanced optical diagnostic tools were used to quantify parameters that cannot be obtained from a normal operation of the engine. The experimental data can be found on the ENERXICO website.

Overall, the results of the combustion research help to provide further understanding of properties that can assist in the decarbonisation in the transportation sector and achieve best performance and minimal environmental impact.

To summarise its work, ENERXICO has launched a white paper which focuses on the reflections about HPC solutions for future demands in the three lines of the project’s research: oil & gas, wind energy and transportation powertrain industries. The ENERXICO white paper is available on the project’s website.